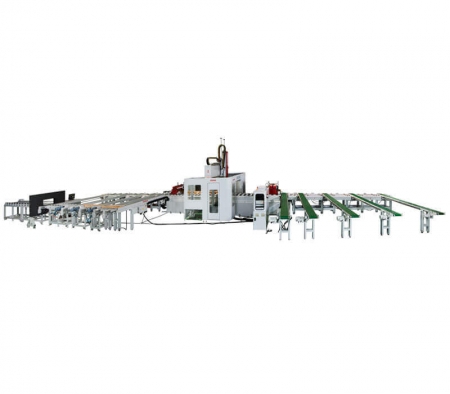

Wood CNC Machining Center

Wood 6-Axis CNC Automatic Production Line

FEATURES:

The 6 axis CNC machining center is an advanced automated production line that integrates multiple processing machines with modular CAM software, automatic front feeding and rear-end outfeeding. Equipped with a barcode spraying system and a wood defect detection system, this CNC machine 6 axis delivers high precision and efficiency for large-scale wood structure processing, such as wooden houses and large furniture.

Key Features:

- Single Spindle with Multiple ATC – Ensures seamless tool changes for enhanced productivity.

- Large Working Area – 10,000 x 650 x 240 mm, accommodating diverse woodworking projects.

- Aluminum Alloy Drum-Type ATC – Features 12 grippers for efficient tool handling.

- Automatic Chip Removal Conveyor – Collects waste material in one location for easy cleanup.

- 6-Face Machining Capability – Ideal for processing log house beams with high precision.

- Auto Inkjet Printing – Prints required words & marks directly on workpieces for better workflow integration.

Upgrade your production with Boarke’s 6 axis CNC machining center and experience precision, automation, and flexibility like never before! Contact us today for a customized solution!